Young’s modulus computation

Background

The computation of the Young’s modulus makes use of look-up tables (LUTs) which are discussed in detail further below. All LUTs are treated identically with respect to the following correction terms:

scaling laws: The original LUT was computed for a specific channel width \(L\), flow rate \(Q\), and viscosity \(\eta\). If the experimental values of these parameters differ from those in the simulation, then they must be scaled before interpolating the Young’s modulus. The scale conversion rules can be derived from the characteristic length \(L\) and stress \(\sigma=\eta \cdot Q/L^3\) [MOG+15]. For instance, the event area scales with \((L_\text{exp}/L_\text{LUT})^2\), the Young’s modulus scales with \(\sigma_\text{exp}/\sigma_\text{LUT}\), and the deformation is not scaled as it has no units. Please note that the scaling laws were derived for linear elastic materials and may not be accurate for other materials (e.g. hyperelastic). The scaling laws are implemented in the submodule

dclab.features.emodulus.scale_linear.pixelation effects: All features (including deformation and area) are computed from a pixelated contour. This has the effect that deformation is overestimated and area is underestimated (compared to features computed from a “smooth” contour). While a slight change in area does not have a significant effect on the interpolated Young’s modulus, a systematic error in deformation may lead to a strong underestimation of the Young’s modulus. A deeper analysis is visualized in the plot pixelation_correction.png which was created with pixelation_correction.py. Thus, before interpolation, the measured deformation must be corrected using a hard-coded correction function [Her17]. The pixelation correction is implemented in the submodule

dclab.features.emodulus.pxcorr.shear-thinning and temperature-dependence: The viscosity of a medium usually is a function of temperature. In addition, complex media, such as 0.6% methyl cellulose (CellCarrier B), may also exhibit shear-thinning. The viscosity of such media decreases with increasing flow rates. Since the viscosity is required to apply the scaling laws (above), it must be corrected which is done using hard-coded correction functions as described in the next section.

Viscosity

The computation of the viscosity is implemented in the corresponding submodule. For regular RT-DC measurements, the medium

used is methyl cellulose (MC) dissolved in phosphate-buffered saline (PBS).

For the most common MC concentrations, dclab comes with hard-coded models that

compute the corresponding medium viscosity. These models are the original

herold-2017 [Her17] model and the more recent

buyukurganci-2022 [BBN+23, RB23] model.

The MC-PBS solutions show a shear thinning behavior, which can be described by the viscosity \(\eta\) following a power law at sufficienty high shear rates \(\dot{\gamma}\):

where \(\dot\gamma\) is the shear rate, \(K\) is the flow consistency index and \(n\) is the flow behavior index. The shear rate inside a square microchannel cannot be described as a single number for a shear thinning liquid. The shear rate is best described by the shear rate at the channel walls as proposed by Herold [Her17] and can be calculated as follows:

These considerations are the foundation for the viscosity calculations in the herold-2017 [Her17] and buyukurganci-2022 [BBN+23] models.

Note

As discussed in [RB23], the herold-2017 model inaccurately models the temperature dependency of the MC-PBS viscosity. The temperature dependency was measured using a falling ball viscometer where the change in shear rate could not be controlled. For the buyukurganci-2022 model, the temperature dependency was measured as a function of shear rate. Take a look at the example script that compares these models to gain more insight.

Warning

Never compare the Young’s moduli computed from different viscosity models. Up until dclab 0.47.8, all values of the Young’s modulus were computed using the old herold-2017 model. For new data analysis pipelines, you should use the more accurate buyukurganci-2022 model.

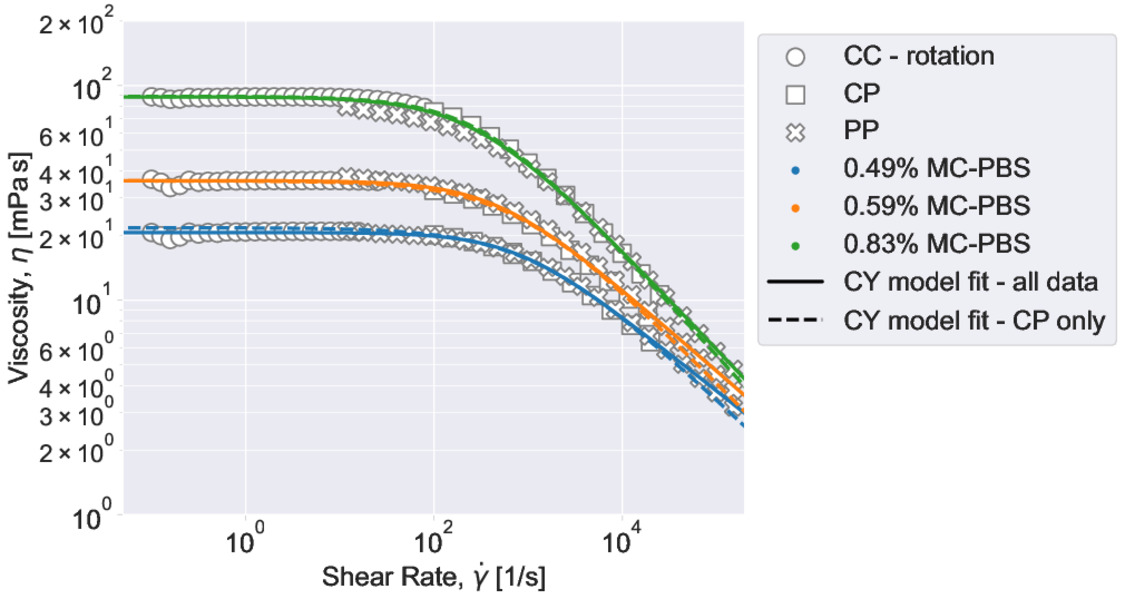

Büyükurgancı 2022

Büyükurgancı et al. characterized the viscosity curves of three MC-PBS solutions (0.49 w% MC-PBS, 0.59 w% MC-PBS, 0.83 w% MC-PBS) in a temperature range of 22-37 °C. As mentioned above, the viscosity follows a power law behavior for large shear rates.

Fig. 1 The viscosity of MC-PBS changes from a viscosity plateau at lower shear rates into a power law behavior at higher shear rates, which can be considered fully developed above 5000 1/s. Shear thinning starts at lower shear rates for higher concentrations of MC-PBS, which is typical for polymer solutions. The viscosity was measured using three viscometer designs: Concentric cylinders (CC), cone plate (CP), and parallel disks (PP). See [BBN+23] for details.

The power law parameters \(K\) and \(n\) were found to be temperature dependent. The temperature dependency can be described as follows:

It was found that \(\alpha\) and \(\lambda\) are not dependent on the

MC concentration and can be considered material constants of MC dissolved in

PBS [BBN+23]. As a result, a global model, valid for the

three measured concentrations of MC-PBS was proposed [RB23]

and implemented here in get_viscosity_mc_pbs_buyukurganci_2022().

LUT selection

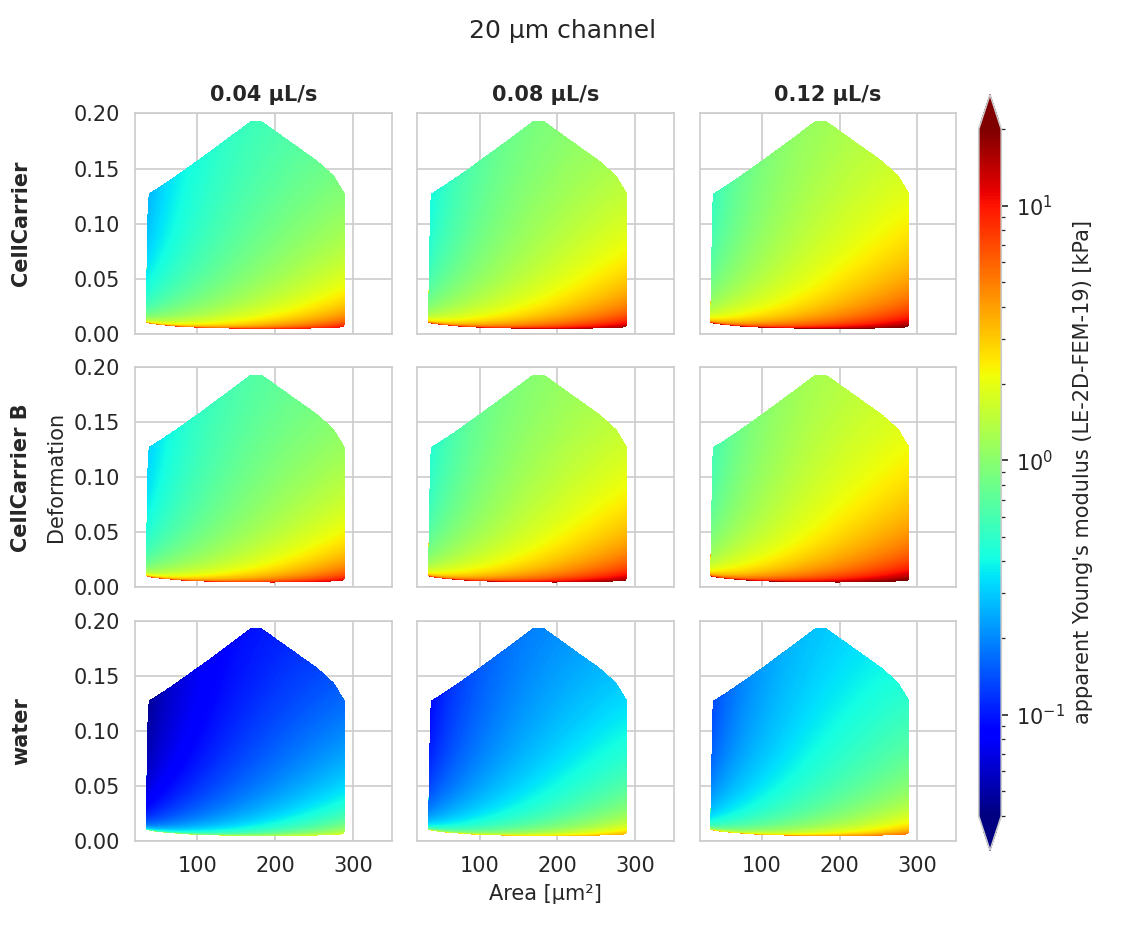

When computing the Young’s modulus, the user has to select a LUT via a keyword argument (see next section). The LUT initially implemented in dclab has the identifier “LE-2D-FEM-19”.

LE-2D-FEM-19

This LUT was derived from simulations based on the finite elements method (FEM) [MMM+17] and the analytical solution [MOG+15]. The LUT was generated with an incompressible (Poisson’s ratio of 0.5) linear elastic sphere model (an artificial viscosity was added to avoid division-by-zero errors) in an axis-symmetric channel (2D). Although the simulations were carried out in this cylindrical symmetry, they can be mapped onto a square cross-sectional channel by adjusting the channel radius to approximately match the desired flow profile. This was done with the spatial scaling factor 1.094 (see also supplement S3 in [MOG+15]). The original data used to generate the LUT are available on figshare [WMM+20].

Fig. 2 Visualizations of the support and the values of the look-up table (LUT) ‘LE-2D-FEM-19’ used for determining the Young’s modulus from deformation and cell area. The values of the Young’s moduli in the regions shown depend on the channel size, the flow rate, the temperature, and the viscosity of the medium [MOG+15]. Here, they are computed for a 20 µm wide channel at 23°C using the viscosity model buyukurganci-2022 with an effective pixel size of 0.34 µm. The data are corrected for pixelation effects according to [Her17].

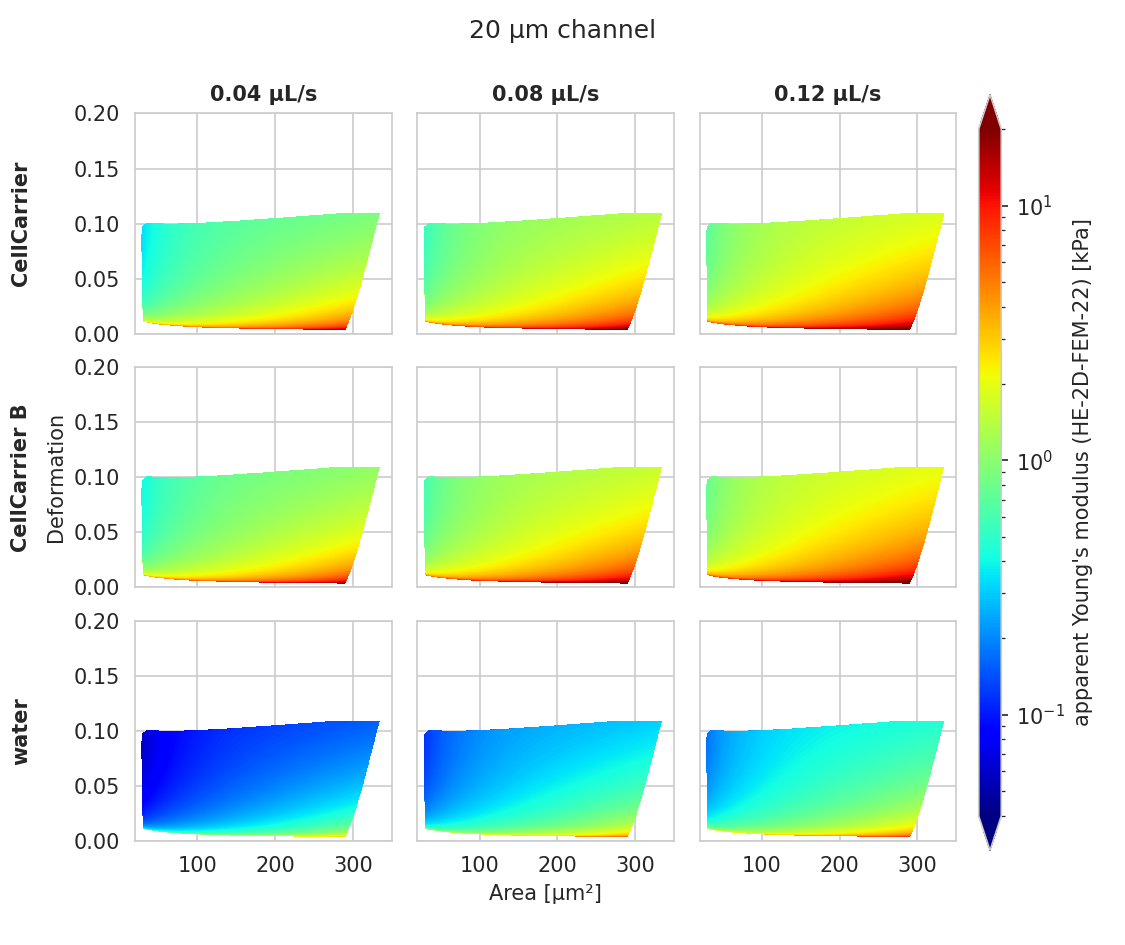

HE-2D-FEM-22 and HE-3D-FEM-22

These LUTs are based on a hyperelastic neo-Hookean material model for cells with a shear-thinning non-Newtonian fluid (e.g. 0.6% MC-PBS). The simulations were done in cylindrical (2D, with same scaling factor 1.094 as for LE-2D-FEM-19) and square channel (3D) geometries as discussed in [WRM+22]. The original data used to generate these LUTs are available on figshare [WMR+22].

Fig. 3 Visualizations of the support and the values of the look-up table (LUT) ‘HE-2D-FEM-22’ [WRM+22] for a 20 µm wide channel at 23°C (buyukurganci-2022 model) with an effective pixel size of 0.34 µm. The data are corrected for pixelation effects according to [Her17].

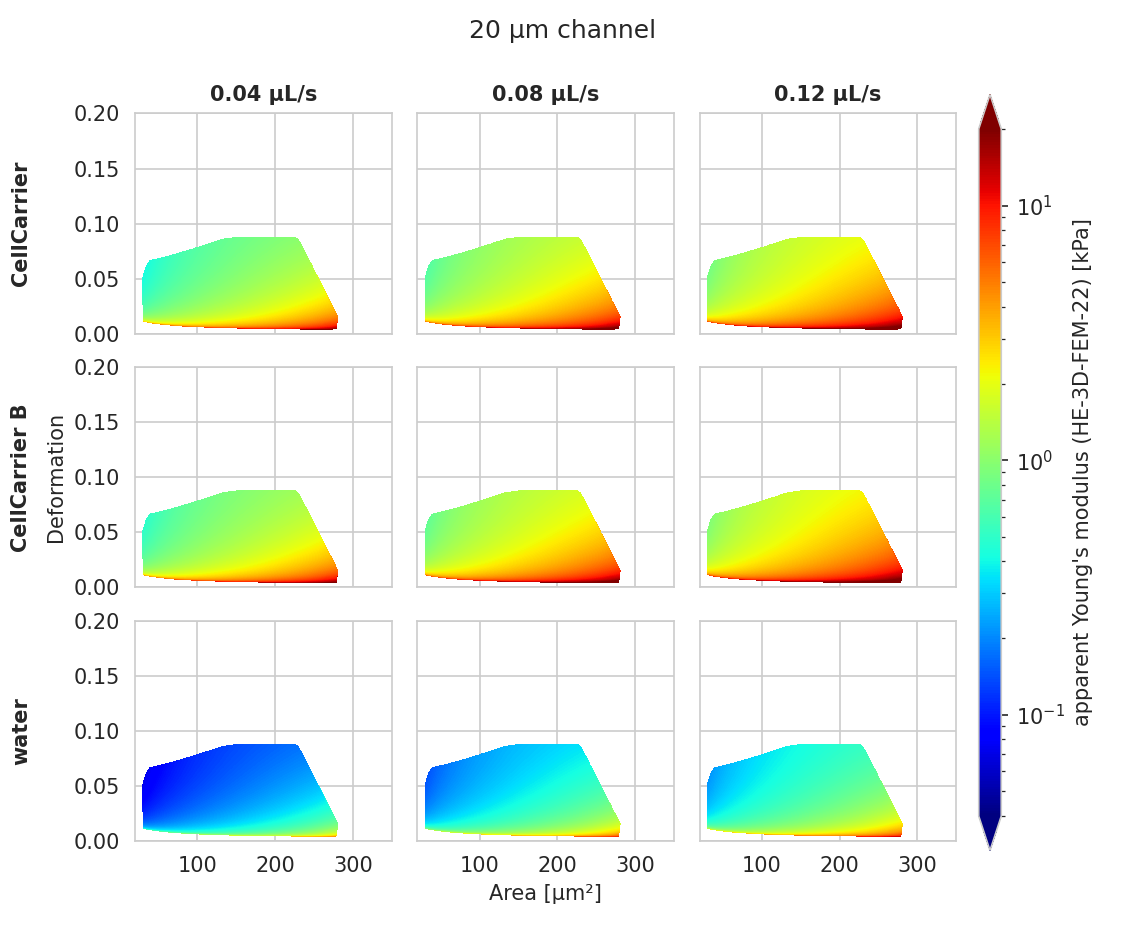

Fig. 4 Visualizations of the support and the values of the look-up table (LUT) ‘HE-3D-FEM-22’ [WRM+22] for a 20 µm wide channel at 23°C (buyukurganci-2022 model) with an effective pixel size of 0.34 µm. The data are corrected for pixelation effects according to [Her17].

external LUT

If you are generating LUTs yourself, you may register them in dclab using

the function dclab.features.emodulus.load.register_lut():

import dclab

dclab.features.emodulus.register_lut("/path/to/lut.txt")

Please make sure that you adhere to the file format. An example can be found here.

Usage

Since the Young’s modulus is model-dependent, it is not made available right away as an ancillary feature (in contrast to e.g. event volume or average event brightness).

In [1]: import dclab

In [2]: ds = dclab.new_dataset("data/example.rtdc")

# "False", because we have not set any additional information.

In [3]: "emodulus" in ds

Out[3]: False

Additional information is required. There are three scenarios:

The viscosity/Young’s modulus is computed individually from the chip temperature for each event:

The temp feature which holds the chip temperature of each event

The configuration key [calculation]: ‘emodulus lut’

The configuration key [calculation]: ‘emodulus medium’

The configuration key [calculation]: ‘emodulus viscosity model’

Set a global viscosity in [mPa·s]. Use this if you have measured the viscosity of your medium (and know all there is to know about shear thinning [Her17] and temperature dependence):

The configuration key [calculation]: ‘emodulus lut’

The configuration key [calculation]: ‘emodulus viscosity’

Compute the Young’s modulus using the viscosities of known media for a fixed temperature:

The configuration key [calculation]: ‘emodulus lut’

The configuration key [calculation]: ‘emodulus medium’

The configuration key [calculation]: ‘emodulus temperature’

The configuration key [calculation]: ‘emodulus viscosity model’

Note that if ‘emodulus temperature’ is given, then this temperature is used, even if the temp feature exists (scenario A).

Description of the configuration keywords:

‘emodulus lut’: This is the LUT identifier (see previous section).

‘emodulus medium’: This must be one of the supported media defined in

dclab.features.emodulus.viscosity.KNOWN_MEDIAand can be taken from the configuration key [setup]: ‘medium’.‘emodulus temperature’: is the mean chip temperature and could possibly be available in [setup]: ‘temperature’.

‘emodulus viscosity model’: This is the viscosity model key to use (see Viscosity above). This key was introduced in dclab 0.48.0.

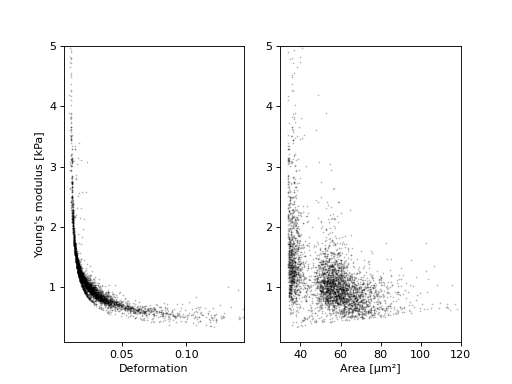

import matplotlib.pylab as plt

import dclab

ds = dclab.new_dataset("../data/example.rtdc")

# Add additional information. We cannot go for (A), because this example

# does not have the temperature feature (`"temp" not in ds`). We go for

# (C), because the beads were measured in a known medium.

ds.config["calculation"]["emodulus lut"] = "LE-2D-FEM-19"

ds.config["calculation"]["emodulus medium"] = ds.config["setup"]["medium"]

ds.config["calculation"]["emodulus temperature"] = 23.0 # a guess

ds.config["calculation"]["emodulus viscosity model"] = 'buyukurganci-2022'

# Plot a few features

ax1 = plt.subplot(121)

ax1.plot(ds["deform"], ds["emodulus"], ".", color="k", markersize=1, alpha=.3)

ax1.set_ylim(0.1, 5)

ax1.set_xlim(0.005, 0.145)

ax1.set_xlabel(dclab.dfn.get_feature_label("deform"))

ax1.set_ylabel(dclab.dfn.get_feature_label("emodulus"))

ax2 = plt.subplot(122)

ax2.plot(ds["area_um"], ds["emodulus"], ".", color="k", markersize=1, alpha=.3)

ax2.set_ylim(0.1, 5)

ax2.set_xlim(30, 120)

ax2.set_xlabel(dclab.dfn.get_feature_label("area_um"))

plt.show()

(Source code, png, hires.png, pdf)